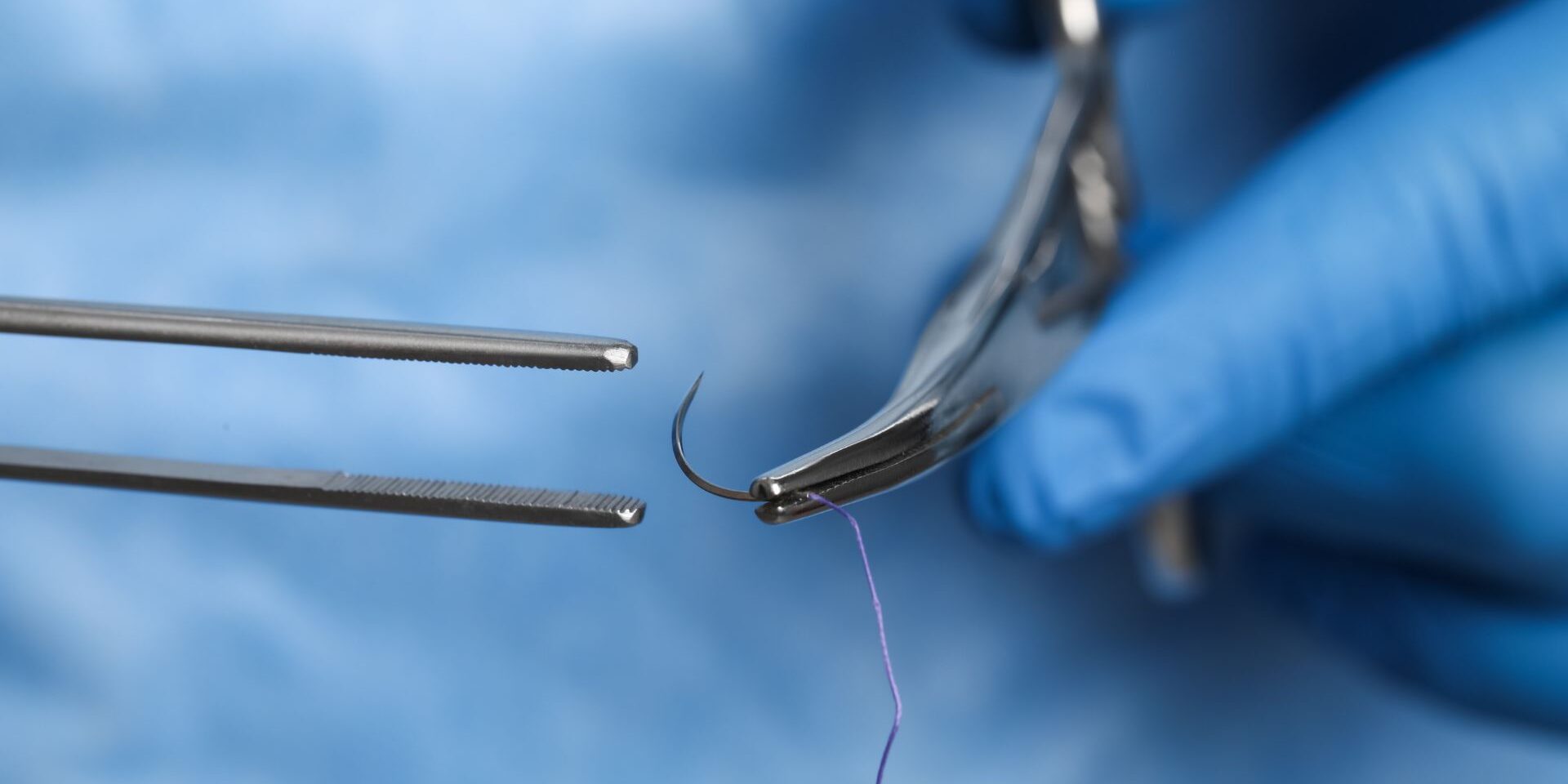

In the intricate world of modern medicine, surgical sutures play a crucial role in closing wounds and facilitating the healing process. Behind the scenes, manufacturing companies specializing in surgical sutures employ cutting-edge technology and precision engineering to produce these indispensable medical devices. This article delves into the realm of surgical sutures manufacturing, shedding light on the processes, innovations, and the vital role these companies play in the healthcare industry.

Crafting Precision with Advanced Materials:

Surgical sutures are no longer mere threads; they are engineered to meet stringent standards of safety, biocompatibility, and performance. Leading manufacturing companies invest heavily in research and development to identify and utilize advanced materials that offer optimal tensile strength, flexibility, and resistance to infections. Polyglycolic acid, polydioxanone, and various absorbable and non-absorbable materials are woven or braided into sutures of different sizes and structures.

Stringent Quality Control:

Manufacturing surgical sutures involves adherence to rigorous quality control measures to ensure the highest standards of safety and efficacy. Every batch undergoes meticulous testing for tensile strength, knot strength, and biocompatibility. Stringent quality checks guarantee that each suture meets the specifications required for various medical procedures, instilling confidence in healthcare professionals and patients alike.

Innovative Manufacturing Processes:

Modern manufacturing companies employ state-of-the-art technologies to produce surgical sutures efficiently. Automated processes, such as precision extrusion and braiding machines, ensure consistency in the diameter, structure, and coating of the sutures. These advanced techniques not only enhance the quality of the final product but also contribute to increased production capacity to meet the growing demands of the healthcare sector.

Customization for Diverse Applications:

Different surgical procedures demand sutures with specific characteristics. Leading manufacturing companies understand the diverse needs of surgeons and hospitals and offer a range of sutures tailored to various applications. From delicate sutures used in ophthalmic surgeries to robust ones for orthopedic procedures, customization is a hallmark of the manufacturing process.

Biodegradable and Absorbable Sutures:

The evolution of medical science has witnessed the rise of biodegradable and absorbable sutures. Manufacturing companies play a pivotal role in developing these sutures that break down naturally within the body, eliminating the need for removal and reducing the risk of complications. The integration of innovative materials and processes ensures these sutures provide optimal healing without compromising on strength.

Meeting Regulatory Standards:

The manufacturing of surgical sutures is subject to stringent regulatory standards set by health authorities worldwide. Reputable companies invest in compliance, adhering to guidelines stipulated by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). This commitment to regulatory adherence ensures the safety and efficacy of the sutures produced.

Conclusion:

Manufacturing companies specializing in surgical sutures are unsung heroes in the healthcare industry, contributing significantly to the success of surgeries and patient outcomes. Their dedication to precision, innovation, and quality control ensures that healthcare professionals have access to reliable and advanced sutures, marking a critical step forward in the evolution of medical technology. As these companies continue to push the boundaries of possibility, the future holds exciting prospects for further advancements in surgical suture manufacturing.