Sutures have been used for thousands of years, and are still the most common method for closing wounds. The first sutures were made from animal tendons and sinew; these days, synthetic materials such as nylon are more commonly used. The purpose of sutures is to hold tissue structures together while they heal and form new tissue. They are made from a variety of materials and are used in several suturing techniques.

The suture characteristics are important to the quality of the wound and its healing.

Suture characteristics include:

- Strength- how well the suture holds up to pulling also referred to as tensile strength.

- Elasticity- how much it can be stretched before breaking.

- Water absorption- how much water a material absorbs( Moisture)

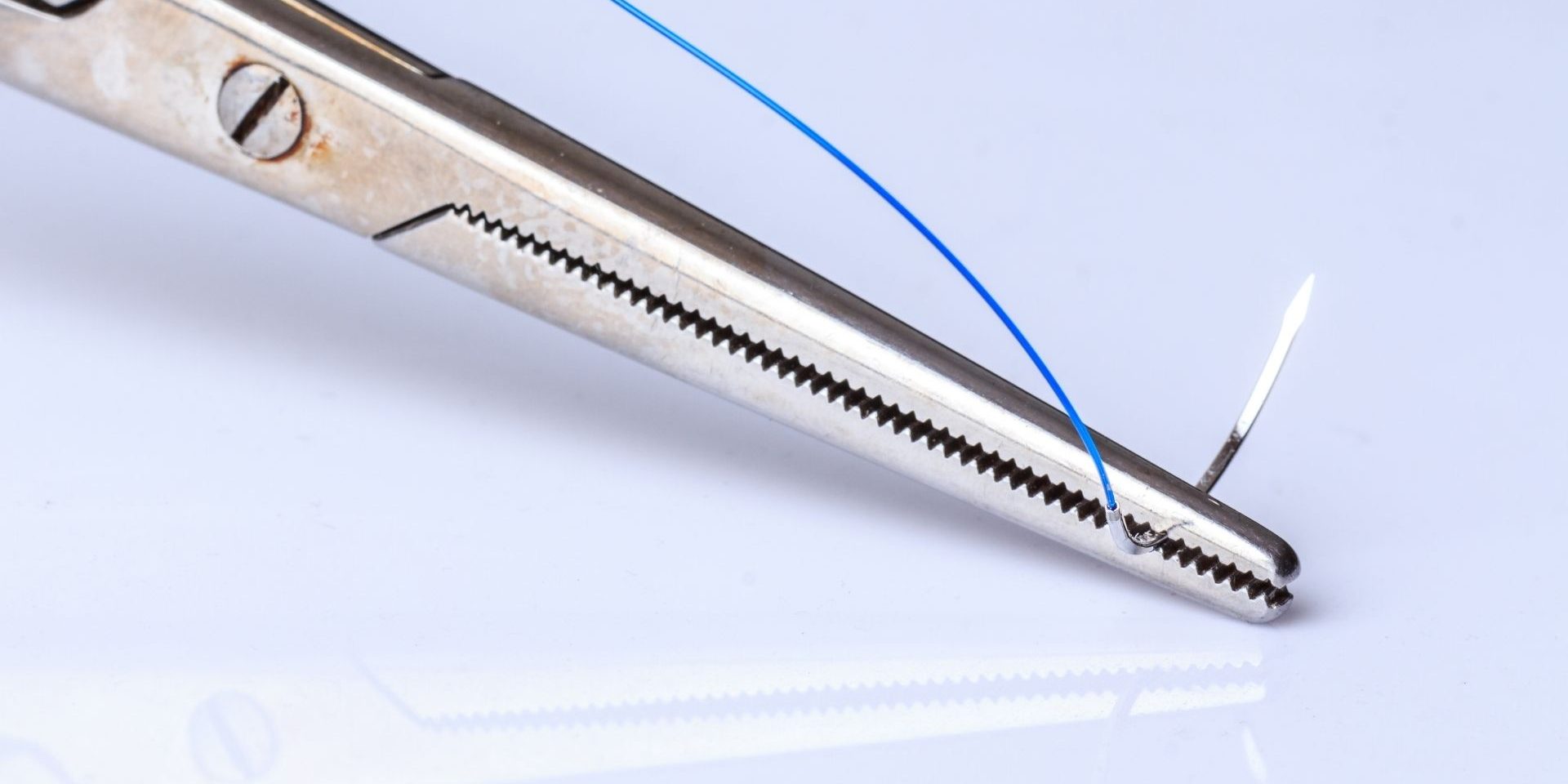

Sutures are the most used method of wound closure. Sutures are thin, thread-like materials that are tied together to hold tissue edges together.

There are many different types of sutures that can be used for various procedures. Typically, the type of suture material will depend on the type of tissue being approximated together. For example, absorbable or non-absorbable sutures may be used depending on whether you want to leave a permanent approximation behind in your patient’s body.

When choosing a suture material, consider what type of approximation you need to make and how long it will take for the wound to heal before deciding which kind is right for you.

Absorption of the Surgical Suture.

The absorption of the surgical suture occurs in two phases. In the first phase, the fascia is reformed with collagen and elastin, and it becomes a dense tissue that is resistant to infection. The second phase involves the absorption of the sutures themselves.

The first phase takes place in about 6 weeks after surgery. The second phase can take up to 3 months for absorbable sutures and up to 6 months for non-absorbable ones.

The absorbable sutures are absorbed by the body’s natural processes, but if you have any concerns about their appearance or how long they will take to disappear, speak to your doctor or surgeon.

Tensile strength of the surgical suture.

The tensile strength of a suture is the force required to break it. Surgical sutures are tested according to USP / BP ( United States of Pharmacopeia / British Pharmacopeia)standard. The test is performed on a single strand of suture and the results are given in kilogram force/ Newton.

During surgery, a surgeon uses many types of surgical sutures that have different strengths. The type and size of the surgical suture depends on several factors, including:

- The patient’s age and weight

- The location where the surgery will be performed

- The type of surgery being performed

Suturing Technique.

The most common suturing technique is simple interrupted sutures. This method allows for easy removal of the sutures later, but it can also result in the creation of large holes in the skin. To minimize this problem, some surgeons use continuous sutures (also called buried stitches).

These are placed deeper into the skin than simple interrupted ones and are made so that they do not come through the skin’s surface. When used on eyelids, continuous sutures also help keep lids from drooping after surgery.

Another option is anastomotic sutures, which are used to repair large wounds or incisions that require stitching together two pieces of tissue (as when repairing a hernia). Because these stitches must remain in place for many weeks or months, they are made from materials that do not dissolve easily and will not irritate surrounding tissue.

Absorption and tensile strength are important factors when choosing a surgical suture.

The material and design of surgical sutures has changed over the years. Here are some basic considerations for choosing a suture:

Absorption and tensile strength are important factors when choosing a surgical suture. Absorption refers to how well a material absorbs body fluids, which helps prevent infection. The tensile strength is how strong the suture is and how easily it breaks when pulled on by force.

Diameter: Smaller diameters are better for internal use because they require less force to pass through tissue, but larger diameters are stronger than smaller diameters at equal lengths.

Sterility: Surgical sutures can be sterile or nonsterile, depending on their intended use and whether they will be exposed to contamination during surgery. Sterile sutures are packaged in boxes labelled “STERILE — FOR SURGICAL USE ONLY.”

How to choose best Surgical Sutures company

Sutures and other products like Hernia Mesh and Bone Wax with best after sales customer support. A good surgical sutures company will also have a great reputation, so it is important to do your research (read reviews) before making any purchases.

Here are some of the qualities to look for in a good surgical sutures company:

- A wide selection of supplies. A good surgical sutures company will have the widest possible selection of medical supplies, including surgical sutures. They should also be able to offer advice on which type of suture is best suited for each procedure or application.

- High quality products. The products you purchase from a surgical sutures company should be high quality and durable enough for use in surgery or other medical procedures. If possible, ask about the materials used in manufacturing these products and how they compare to other brands on the market today.

- Competitive Pricing. While price is not always an indicator of quality when it comes to medical supplies, it still plays an important role in determining what companies stand out from others in this field and why they deserve your business over others who may offer similar services but at higher prices than what you can find elsewhere

How to choose best Surgical Sutures company

Unisur lifecare an EN ISO & CE certified medical devices company focused to enhance the quality of life by ”HEALING BEYOND COMFORT” Universal Sutures is one of the forefront Surgical Sutures Manufacturing Company in India, focused on the design, development, manufacturing, supply, and export of surgical Sutures, Hernia Mesh, and Bone Wax range of products which will be supplied to around 93 countries across the globe.

Our advanced and flexible manufacturing techniques deliver a high-quality product, to suit OEM / OBL Sutures requirements, and value appearance and packaging. We are the Fastest-Growing Manufacturing Company in India, with an annual growth of 47 percent. Our key products are Surgical Sutures, Polypropylene Mesh and Bone Wax.

Our advanced and flexible manufacturing techniques deliver a high-quality product, to suit OEM / OBL Sutures requirements, and value appearance and packaging. We are the Fastest-Growing Manufacturing Company in India, with an annual growth of 47 percent. Our key products are Surgical Sutures, Polypropylene Mesh and Bone Wax.

We have a total workforce of nearly 200 employees comprising more than 70% women and rest being men. We are focused to continuously develop and bring in innovative products to the industry through a sustained R & D.

Few of the recent innovative products are special crimped needles with unmatchable at- attachment strength in the sutures industry, Unique Closure Cassettes, Plug Mesh, UHMWPE Sutures, Barbed Sutures, Hernia Mesh With Blue Orientation Lines And Few Others.